About Yuanjiu

- Quality first, service first

- Continuously innovating and pursuing excellence

- Provide users with satisfactory products and services!

- Integrity management, building a first-class enterprise

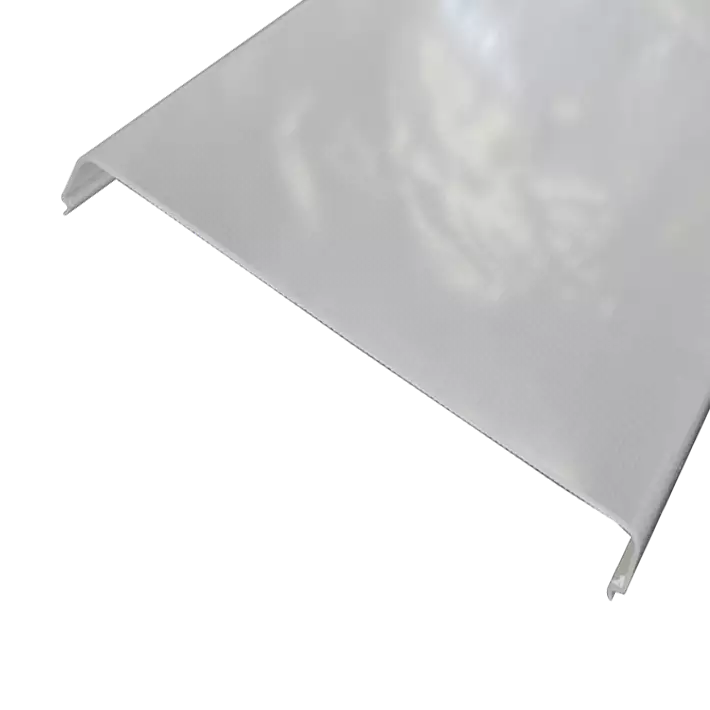

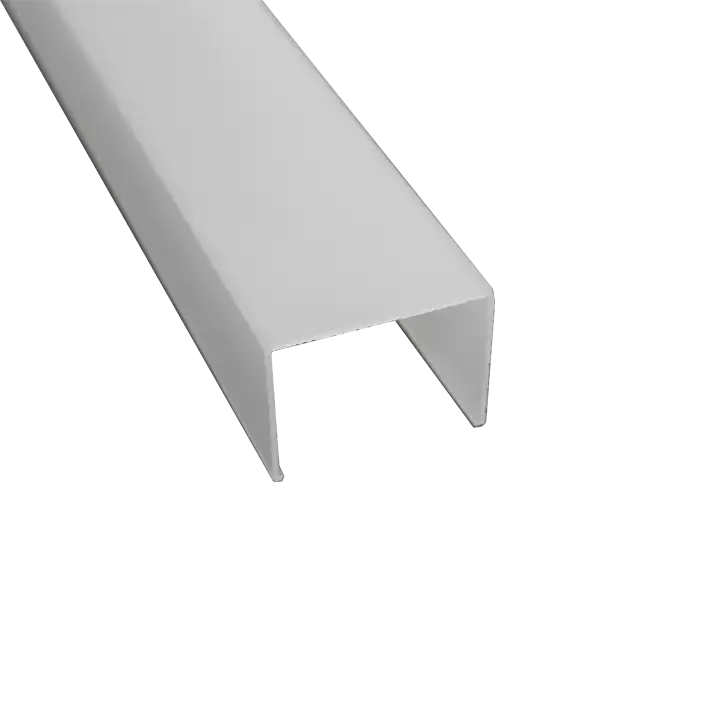

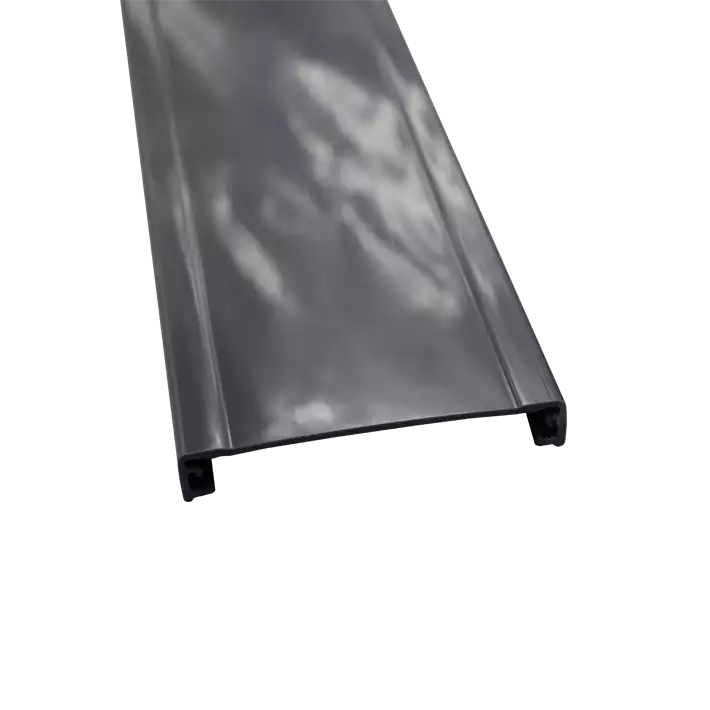

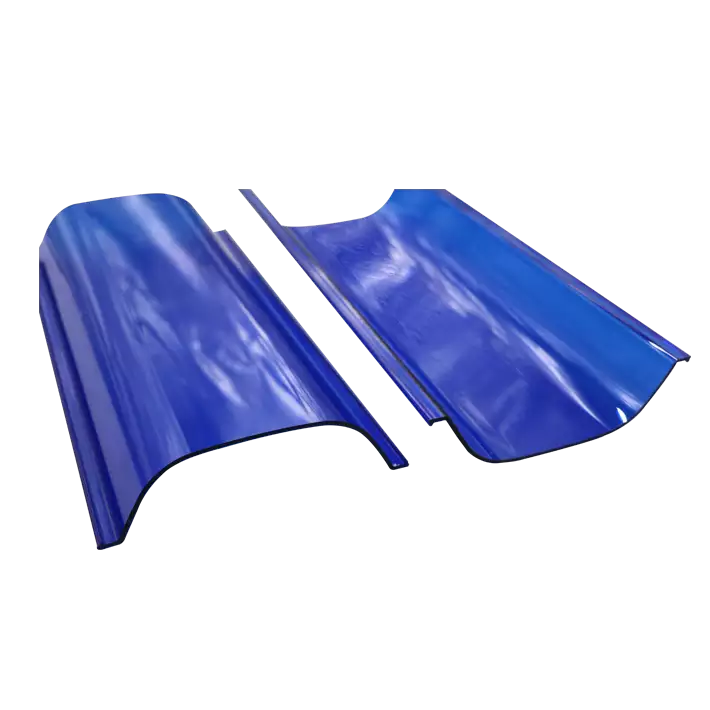

Hot product

Why choose us?

-

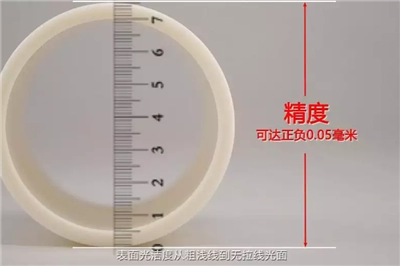

The company has several advanced fully automatic CNC plastic pipe production equipment, as well as advanced domestic quality testing equipment for raw materials and pipe products.

The company has six extrusion workshops, with over 60 extruders in total; Dust free injection molding workshop, with 18 injection molding machines.

-

The company has established its own research and development center, strictly controlling product quality from the entry of raw materials into the factory. All performance indicators of the product meet the requirements of national standards.

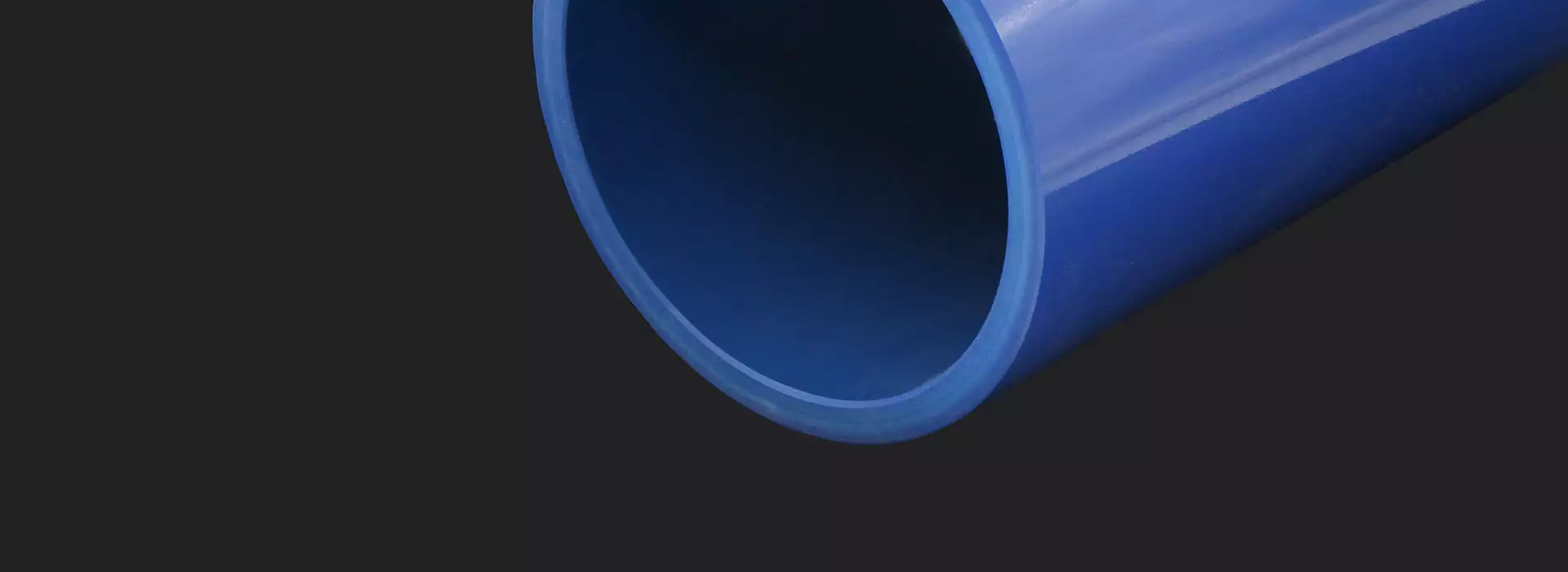

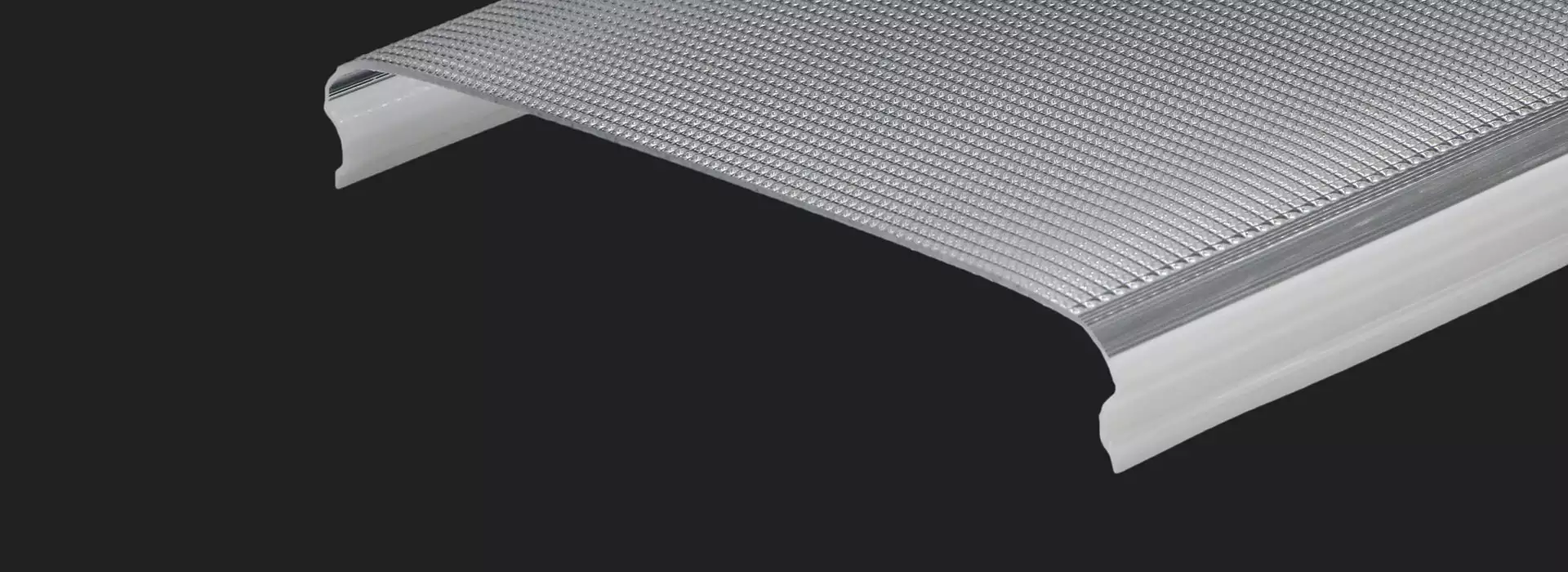

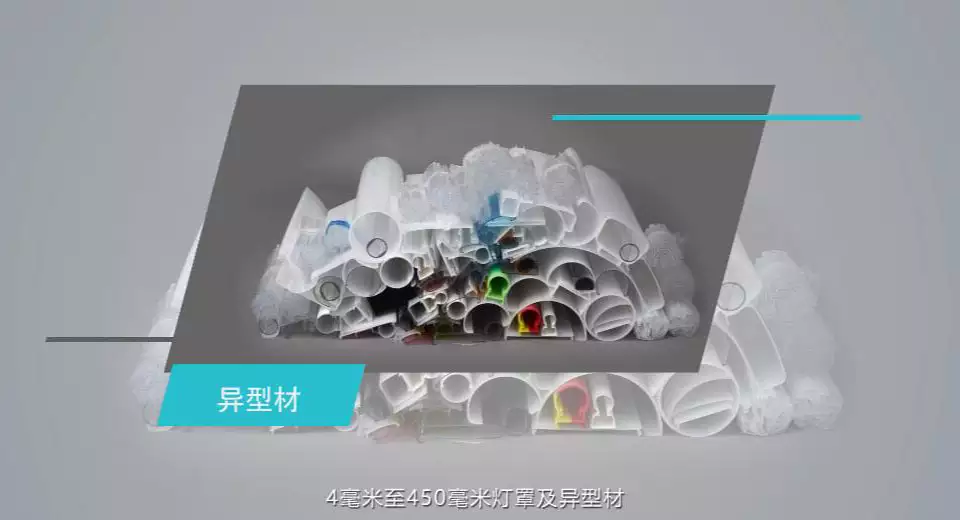

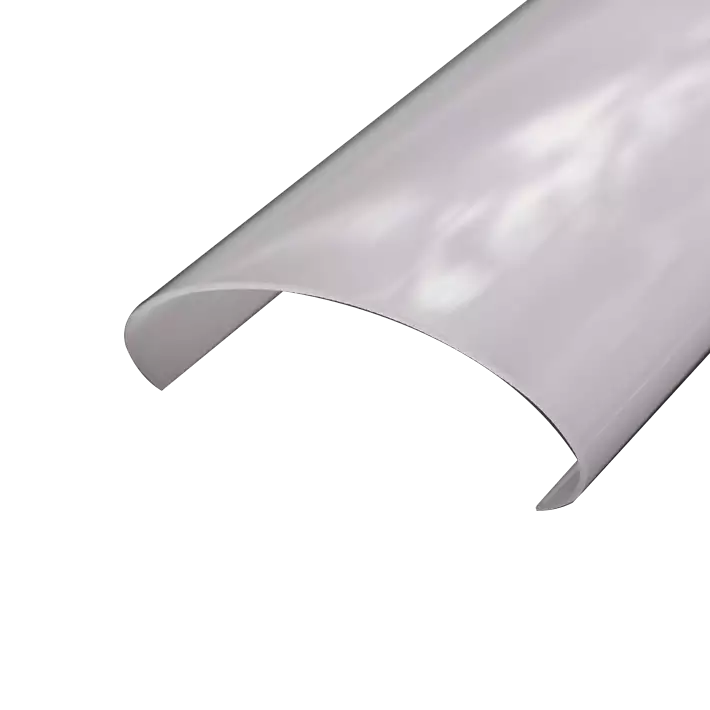

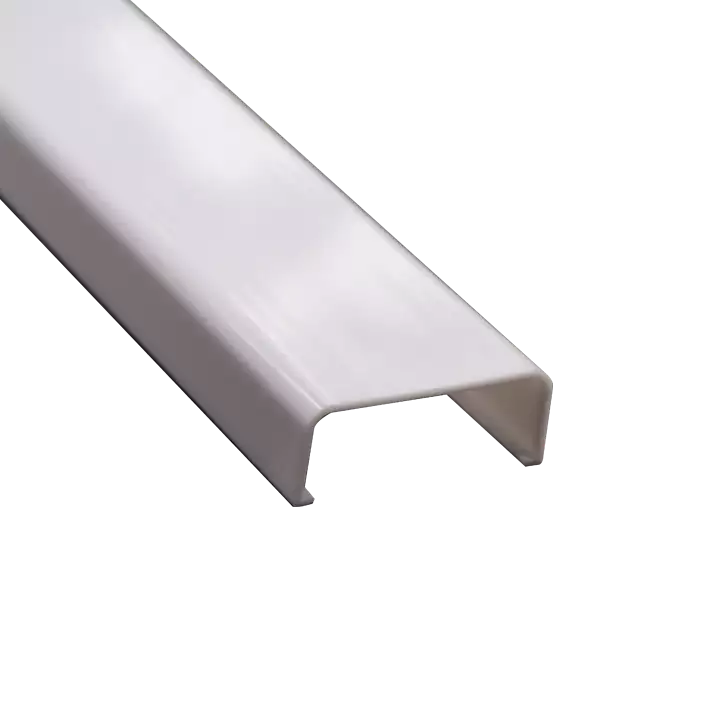

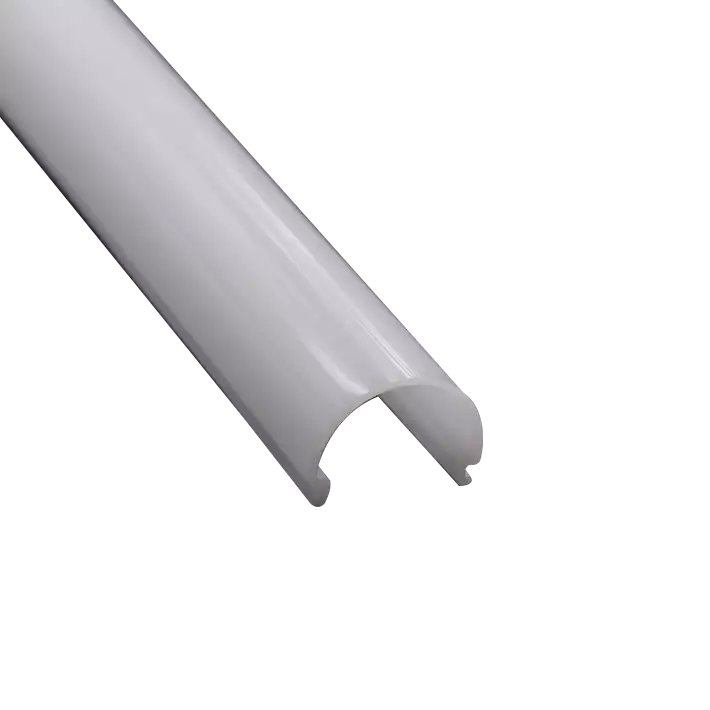

The company mainly deals with large PC/PMMA lampshades, three proof lampshades, explosion-proof lampshades, frosted lampshades, and PVC, PP, PE plastic profile series and other plastic pipe and profile products.

-

With customer demands as the service principle, a professional service team and responsive service, we are always ready to solve your problems.

Winning customers with quality and service, driving sustainable and healthy development of the enterprise with management, Futong Plastics has won high praise from numerous customers with high-quality products and comprehensive services!

News Center

Faq

If you want to customize a batch of lampshades, you need to consider and provide the following parameters and information to the manufacturer or designer:

1. * * Material Selection * *: Determine the material you want the lampshade to use, such as painted metal, glass, acrylic, fabric, or wood shavings weaving. Each material has its specific visual effects and suitable environment.

2. * * Size specifications * *: Provide specific dimensions of the lampshade, including diameter (upper and lower openings), height, and shape (such as circular, square, conical, etc.). Ensure that these dimensions match your lamp base.

3. * * Decorative effect * *: Describe the desired decorative style, such as minimalism, retro, industrial style, or cozy home decor, which will affect the design and surface treatment of the lampshade.

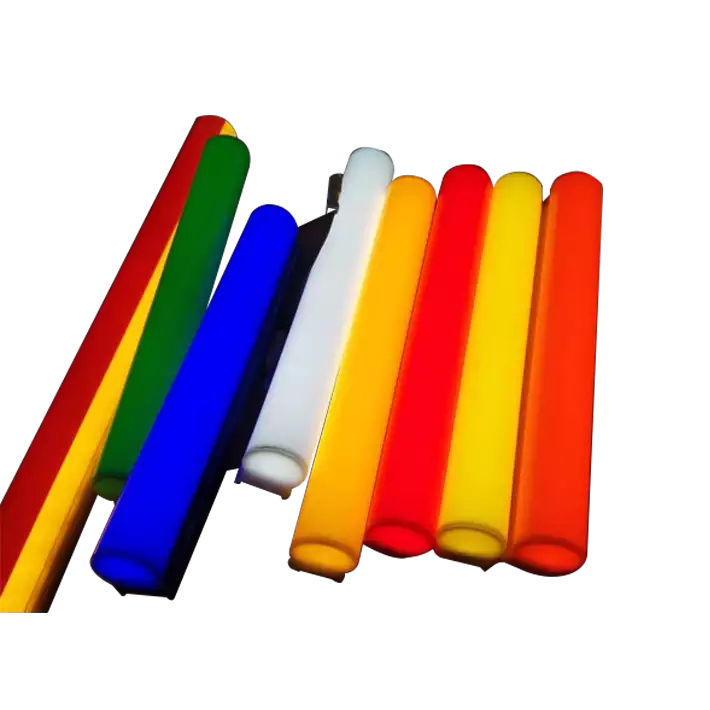

4. * * Color Requirements * *: Specify the color of the lampshade, considering the impact of color on light penetration and atmosphere. White usually has good light transmittance, while black or color may reduce light penetration and produce different light and shadow effects.

5. * * Pattern or Texture * *: If there are specific patterns, textures, or custom designs (such as hollow patterns), detailed design drawings or explanations must be provided.

6. * * Installation method * *: Explain how the lampshade is fixed to the lamp holder, including any specific installation hardware or interface requirements.

7. * * Functional requirements * *: such as whether it is necessary to have light transmittance adjustment function (such as frosting treatment), easy cleaning, or special optical characteristics.

8. * * Quantity * *: Clearly specify the quantity of customization, as mass customization may have a price advantage.

9. * * Delivery Time and Budget * *: Provide your expected delivery time and budget range for the manufacturer to evaluate feasibility.

10. * * Contact Information * *: Ensure accurate contact information is provided so that the manufacturer can communicate details, confirm design drafts, and progress with you.

After preparing the above information, you can contact a professional lampshade manufacturer or designer for in-depth discussion and customized services.

The PC lampshade itself does not directly include a switch, and the switch type is usually part of the overall design of the lamp, rather than unique to the lampshade. The lampshade is mainly used to protect the light source and control the direction and effect of light scattering. Therefore, when it comes to "switch types" such as button type, pull type, touch type, etc., this usually refers to the switch mechanism on the lamp, rather than the properties of the lampshade.

As for the sizes of PC lampshades, they are very diverse and can be customized or standard sizes can be selected according to specific application requirements. From the provided information, some example sizes can be seen, such as:

-The outer dimensions of the PC lampshade for the bright gold lighting DJ-08-3 are diameter 180 * H1000 (mm).

-The cylindrical PC lampshade has a specification of 76 * 62 * 2.0MM, suitable for corn lamps or bubble lamps.

-The PC lampshade for industrial and mining lamps comes in various sizes, such as 12 inches, 16 inches, 19 inches, 22 inches, etc.

-The diameter of the 138mm light diffusion lampshade is 138mm and the height is 10mm.

The selection of size should be based on the type of lamp, installation location, and required lighting effect. When customizing, you can propose specific size requirements based on actual needs, including diameter, height, and specific shape specifications. In addition, the thickness, color (transparent, milky white or other colors), and light transmittance of PC lampshades are also factors that need to be considered when customizing.

PC can be injection molded, extruded, molded, blow molded, thermoformed, printed, bonded, coated, and machined, with injection molding being the most important processing method.

PC (Polycarbonate) is the abbreviation for polycarbonate or polycarbonate, abbreviated as PC engineering plastic. PC material is actually one of the engineering plastics that we refer to. As a widely used material worldwide, PC has its own characteristics and advantages and disadvantages. Firstly, PC is an amorphous thermoplastic resin with excellent comprehensive performance, which has excellent electrical insulation, elongation, dimensional stability, chemical corrosion resistance, high strength, heat resistance, and cold resistance; It also has advantages such as self extinguishing, flame retardant, non-toxic, and colorability. You can see the shadow of PC plastic in every corner of your life, and its large-scale industrial production and easy processing characteristics also make its price extremely low. Its strength can meet various needs from mobile phones to bulletproof glass, but the disadvantage is that it has insufficient hardness compared to metal, which makes its appearance more prone to scratches. However, its strength and toughness are good, whether under heavy pressure or general impact, it has sufficient longevity.

High density hard core pipes usually refer to pipes made from high-density polyethylene (HDPE) as raw material and processed through specific processes, which have high hardness and good insulation performance. This kind of pipe is often used in the thermal insulation pipeline system as the outer protective layer of the thermal insulation layer, wrapped outside the thermal insulation materials (such as polyurethane rigid foam plastic) and the inner pipes (such as steel pipes). The following are some main characteristics and applications of high-density hard core tubes:

###Main features:

1. * * High mechanical strength * *: High density polyethylene material endows pipes with excellent mechanical properties, which can withstand ground loads, soil pressure, and external impacts, protecting internal pipelines from damage.

2. * * Corrosion resistance * *: HDPE material has good chemical stability, can resist the erosion of various chemicals, and extend the service life of pipeline systems.

3. * * Thermal insulation performance * *: It can effectively reduce heat transfer in combination with efficient thermal insulation materials such as polyurethane rigid foam, and is suitable for the transmission of various cold and hot media to maintain transmission efficiency.

4. * * Waterproof performance * *: High density polyethylene has good sealing properties, which can prevent water infiltration and protect the insulation layer from moisture.

5. * * Easy to install * *: Lightweight and relatively flexible, convenient for on-site construction and installation, reducing joints and lowering installation costs.

6. * * Long service life * *: stable material, anti-aging, long expected service life, low maintenance cost.

###Application field:

-Building heating: used for insulation of underfloor heating systems and residential heating pipelines, to improve energy efficiency.

-Air conditioning refrigeration: The refrigerant pipes in the air conditioning system are insulated to reduce energy loss.

-Petrochemical: Pipeline insulation in the petrochemical industry, protecting pipelines from environmental corrosion and maintaining medium temperature.

-Hot water supply: insulation of hot water pipelines in hotels, residential areas, and other areas to ensure the quality of hot water.

-Food industry: Pipeline insulation in food processing meets hygiene standards while reducing heat loss.

-Centralized heating and cooling system: As a key insulation component in urban centralized heating and cooling systems.

In summary, high-density hard coiled tubing is an important industrial and civil insulation material, which has been widely used in multiple fields due to its excellent physical and chemical properties.